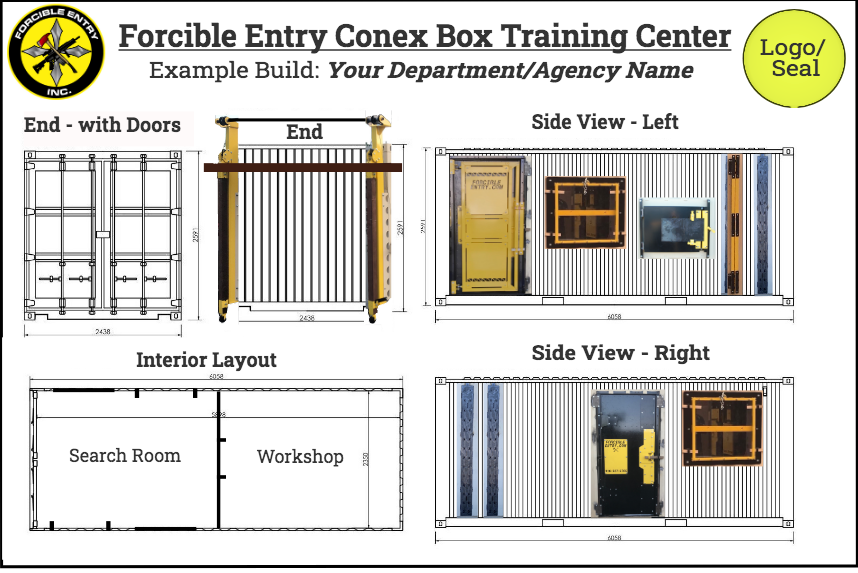

Production & Installation: Step-by-Step

Once your design is finalized and a production schedule is created construction begins on your Conex Box Training Center. Below is the production list and photo slideshow of the build phases:

Proof Approval / Design Finalized

Using the proof we agree upon, we map out, measure, and label the inside and outside of the Container with the specific location of each prop.

Phase 1: Map out the full layout of props and install the Catalyst Force Entry Doors

Catalyst Force Entry Doors are always installed first:

- Measure

- Cut out the rough opening for the door frame

- Grind down the edges

- Frame the interior with square tubing / Mount and Weld to interior walls

- Install Catalyst Force Entry Door Direct Mount Door Frame

- Bolt in the Door frame to the interior frame, hang the doors, and test.

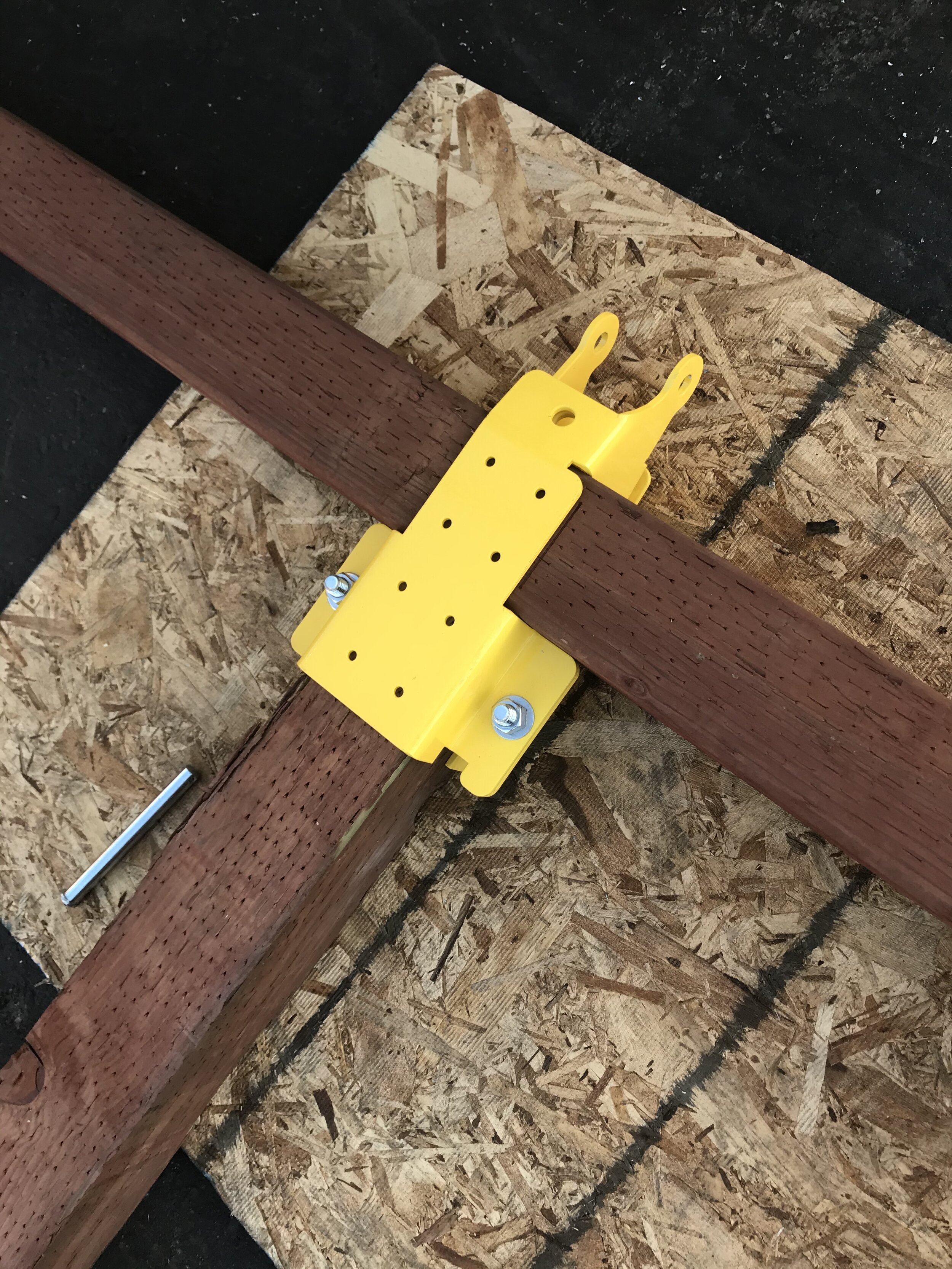

Phase 2: Install the Grid System

Grid System: Welded for Bolt-On Modularity

- We weld in our Bolt-on Grid System into the outer walls of your Conex Box in the specific locations agreed upon.

- This allows you to affix and detach all of our bolt-on Forcible Entry props seamlessly and easily based on your training cycles.

Phase 3: Install the VES 3-in-1 Window (w/ Window Bar) Prop

- Measure / Cut rough opening

- Frame / Mount

- Bolt-in inner and outer frames of the VES Window

Phase 4: Install the Roll-Up Door +/- Roll-Up Door: Man Door Bird Beak option

- Measure / Mount I-Beam sleeves

- Weld I-beam sleeves into Conex Box

- Weld mounting plate for hand crank and bolt-on hand crank

Phase 5: Interior Renovation (optional)

Based on your design, we may be installing an additional wall; wall mounting brackets, a rack(s) to hang tools, saws, and irons; whiteboards; storage containers; workbenches; etc.